STEP 1- Gather your ideas.This can be in the form of sketches, reference samples, tear sheets (from magazines or other media), screenshots. Collecting swatches of fabric could be a good idea.

STEP 2- Set up your consultation. Bring your items collected in step 1, if applicable.

STEP 3- Get your spec sheets approved. Your spec sheets will be sent to you via email, or you can review them in person. The spec sheet is the starting point to your garments, accessories or product. It’s a digital technical representation of your product front and back with fabric and trim callouts, measurements, and other important details pertaining to your project.

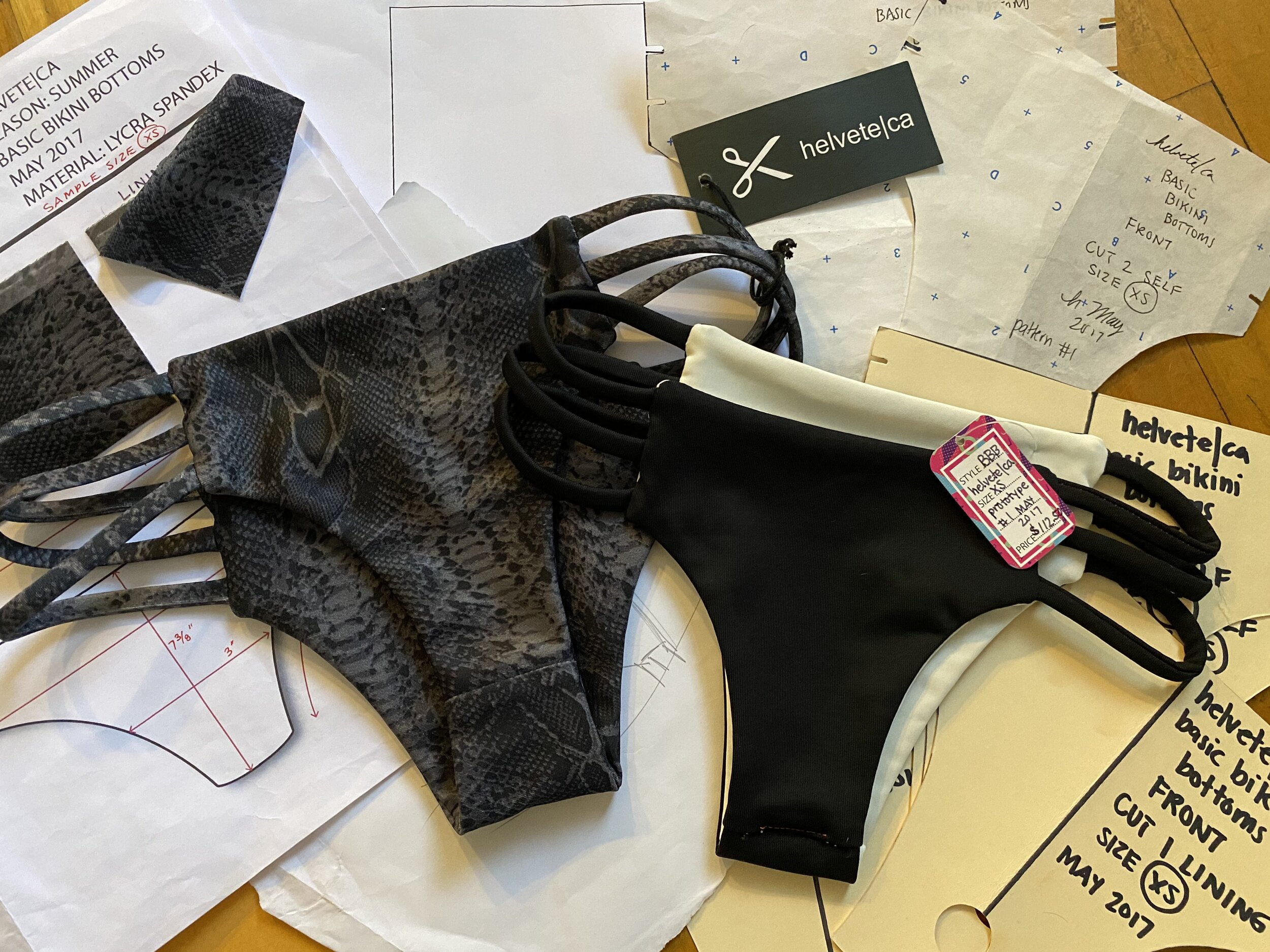

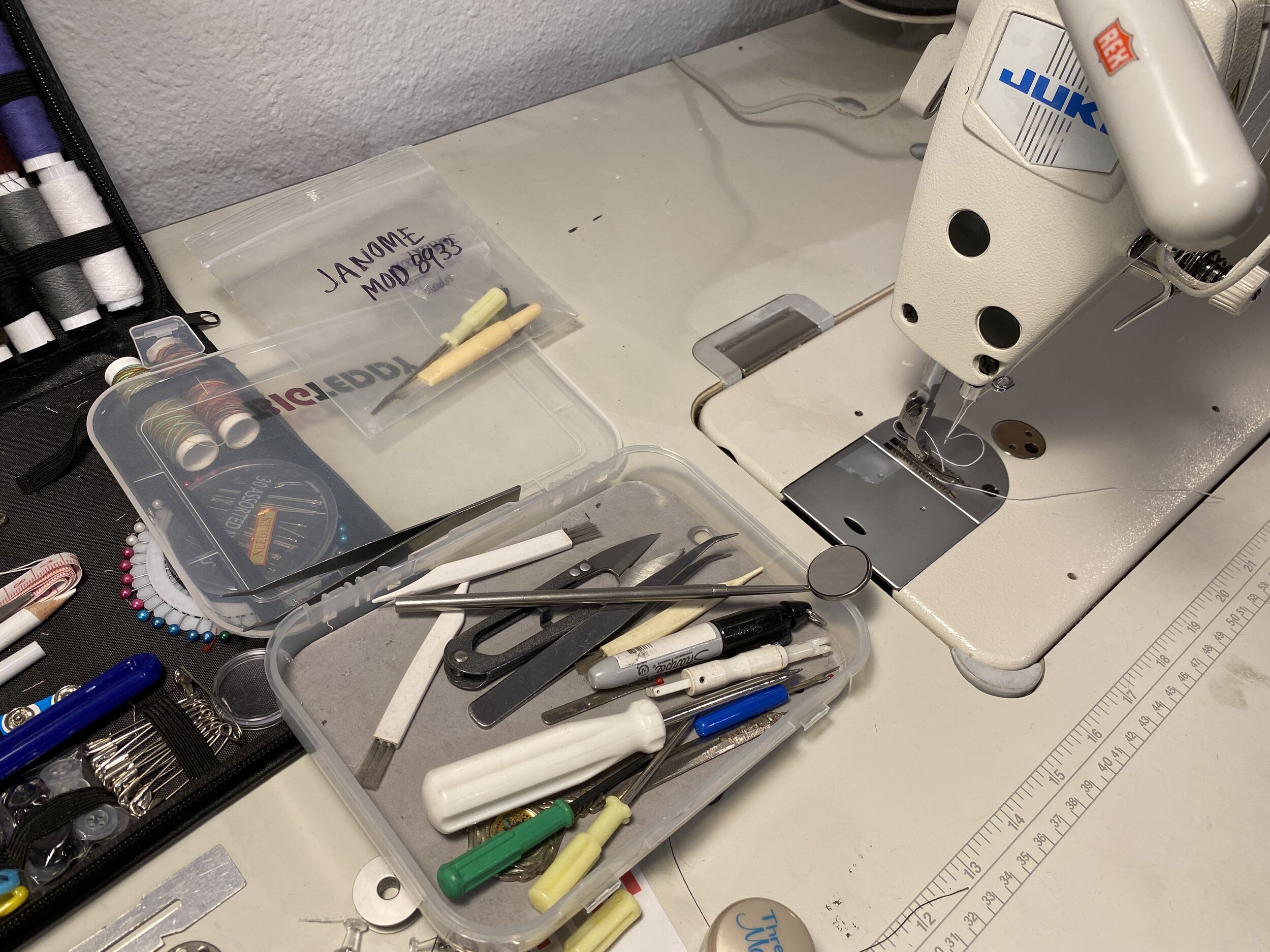

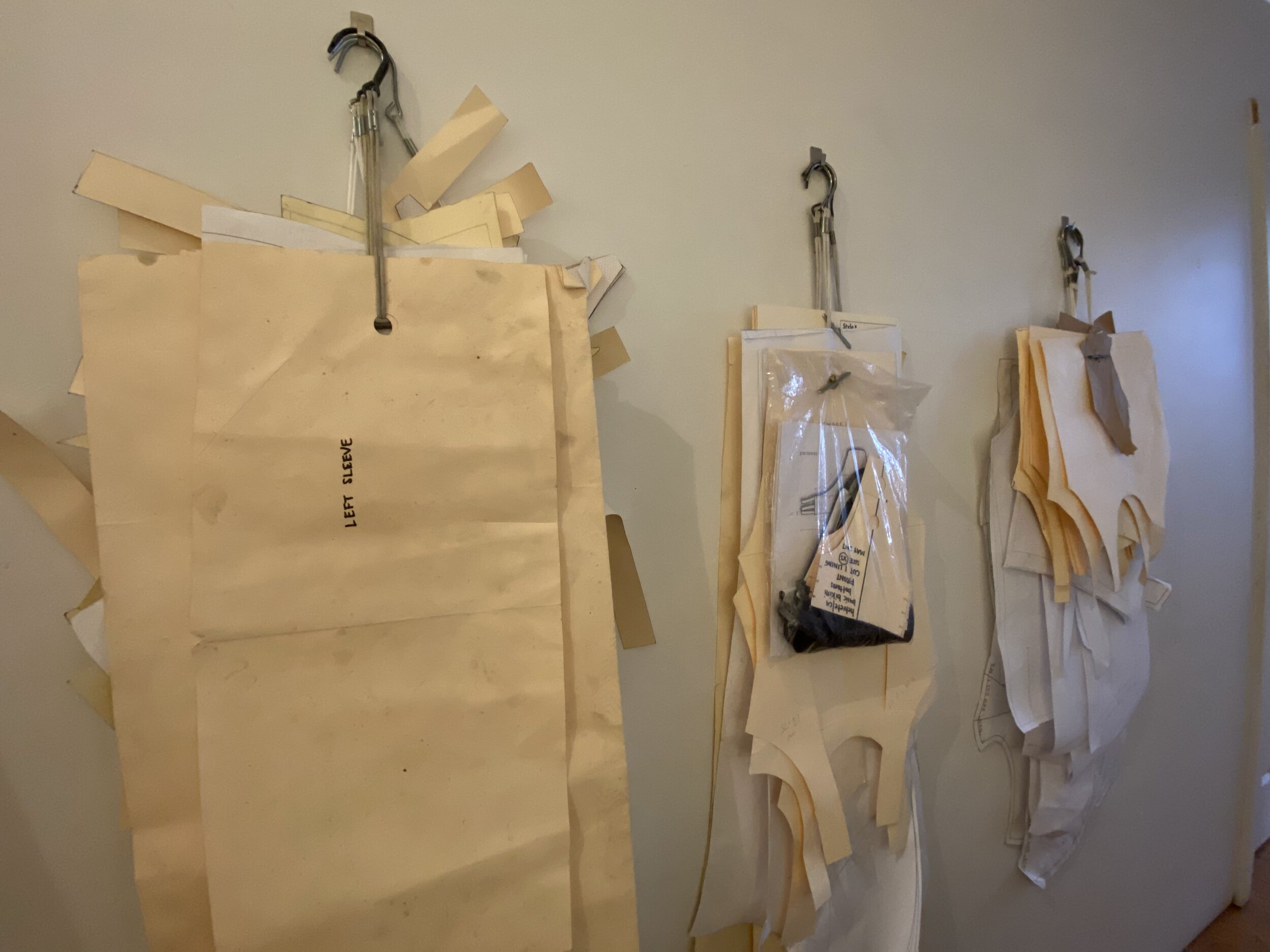

STEP 4- Wait for your first working pattern and prototype to be completed. During this time, your pattern will be drafted according to the approved specs. After, the sample will be created from the pattern. We can supply the fabric and trims for your first sample / prototype free of charge, or you may supply your own.

STEP 5- Come in for a fitting, or to review the completed first sample / prototype. During a fitting, we will take notes of how the garment is fitting, what needs to be changed, if the fabric is appropriate for the garment, etc. If changes need to be made, we will alter the patterns according to the fitting. NOTE: You will need to use the same fit model throughout all fittings.

STEP 6- Moving on to second sample. The second sample, or prototype, will be made in all the fabrics and trims desired for the final sales piece. Most if not all alterations and fitting issues should be addressed and corrected at this point.

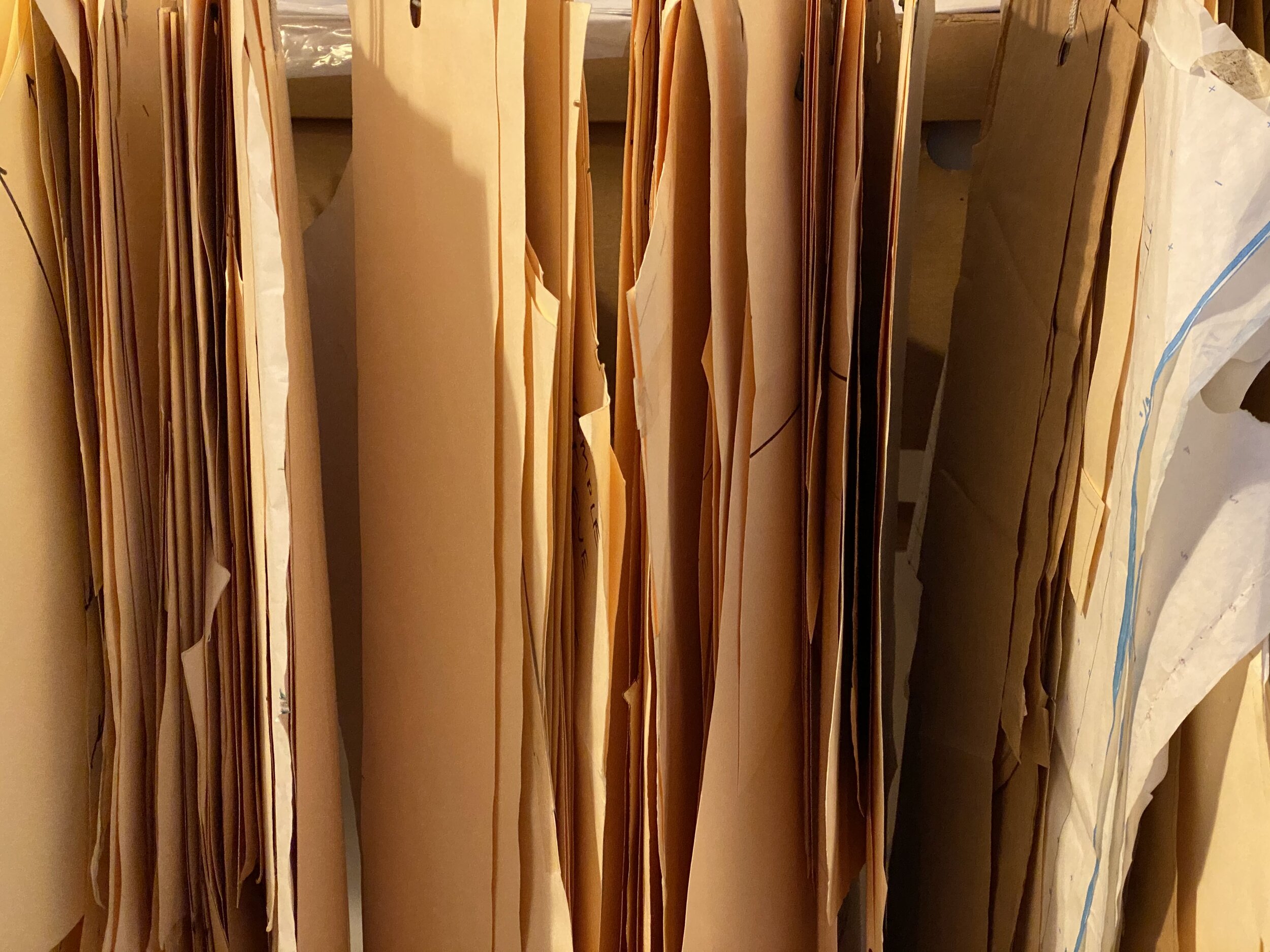

STEP 7- Once the sample has been approved, it’s last approved pattern will be transferred to oaktag (official production pattern), and optionally digitized. All appropriate labels will be marked and punched.

STEP 8- Grading. All desired sizes will be created from the original pattern, also labeled and punched. Digital grading optional.

STEP 9- Sourcing fabrics. At this point, you will need to order the appropriate yardages of fabric, linings, trims, labels, hang tags, and any other materials required for production.

STEP 10- Decide on your production order. You will need to pick out your color run, order quantity, size quantity, packaging, and more.

STEP 11- Review your pre production samples for approval prior to starting production.